What is the best quality PVC for ID cards?

- ID CARD FACTORY

- 4 days ago

- 3 min read

The best quality PVC for ID cards is virgin, high-grade PVC manufactured specifically for ID card and smart card applications, combined with multi-layer construction and heat-based lamination. In India, professional ID card manufacturers use CR80-grade PVC sheets with protective overlays to ensure strength, flexibility, print clarity, and long-term durability. Factory-direct manufacturers like ID CARD FACTORY rely on these standards to produce ID cards that last for years under daily use.

This guide explains what “best quality PVC” actually means, how to identify it, and why it matters for schools, offices, colleges, and institutions.

Introduction

Not all PVC used in ID cards is the same. Two cards may look identical on day one but perform very differently after a few months. Low-grade PVC bends permanently, cracks at edges, fades under sunlight, or peels after lamination. High-quality PVC maintains shape, color, readability, and scan performance even in harsh Indian conditions such as heat, humidity, sweat, and dust.

Understanding PVC quality helps organizations avoid repeated reprints and unnecessary costs.

Virgin PVC vs Recycled PVC (Most Important Difference)

Virgin PVC (Best Quality)

Virgin PVC is made from fresh polymer resin without recycled content.

Key benefits:

Uniform thickness and density

High flexibility without cracking

Excellent print adhesion

Clean lamination bonding

Long lifespan

This is the preferred and recommended PVC for professional ID cards.

Recycled or Mixed PVC (Lower Quality)

Recycled PVC may:

Contain impurities

Have uneven thickness

Crack near punched areas

Show color inconsistency

It is cheaper upfront but unsuitable for long-term ID cards.

CR80-Grade PVC (Industry Standard)

The best quality PVC ID cards follow the CR80 international standard, which defines:

Standard card size

Uniform thickness

Smooth surface finish

CR80-grade PVC ensures:

Compatibility with card readers and printers

Smooth use in holders and lanyards

Consistent feel across batches

Any professional ID card should meet CR80 specifications.

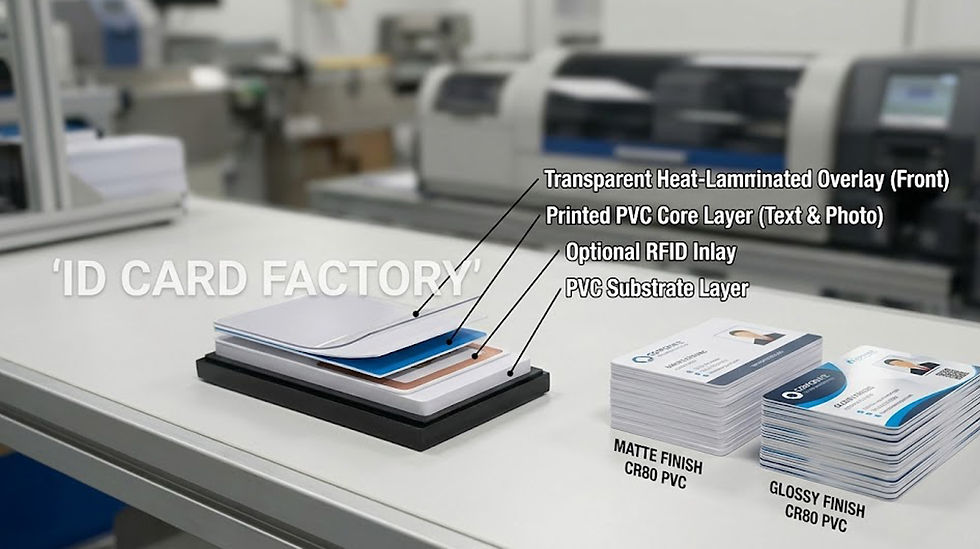

Multi-Layer PVC Construction (Critical for Quality)

High-quality PVC ID cards are never single-sheet.

They consist of:

Printed PVC core layer (photo, text, logo)

Transparent overlay layers on one or both sides

Heat-and-pressure fusion bonding

This structure prevents peeling, surface damage, and fading.

Best Lamination Material for PVC ID Cards

Lamination quality directly affects PVC performance.

Heat-Laminated PVC Overlays (Best)

Fused permanently with the card

Scratch-resistant

Moisture-proof

Long-lasting clarity

Cold Lamination (Avoid)

Adhesive-based

Peels over time

Traps dust and moisture

Only heat lamination should be used for premium PVC cards.

Surface Finish: Matte vs Glossy PVC

Both are high quality when laminated properly:

Glossy PVC

Bright colors

Smooth surface

Easy to clean

Matte PVC

Reduced glare

Premium corporate appearance

Better readability under lighting

Choice depends on usage, not quality difference.

PVC Quality for Barcode, QR, and RFID Cards

Best-quality PVC supports:

Sharp barcode and QR printing

Embedded RFID inlays

Stable scanning performance over time

Poor PVC warps during lamination and causes scan failures.

Thickness and Flexibility Balance

High-quality PVC:

Is flexible but returns to shape

Does not crease permanently

Does not feel brittle

Too thin = bends easilyToo hard = cracksThe best PVC balances strength and elasticity.

How to Identify High-Quality PVC Before Ordering

Ask your supplier:

Is the PVC virgin or recycled?

Does it meet CR80 standards?

Is lamination heat-based?

Is the card multi-layered?

Can repeat batches match exactly?

Clear answers indicate professional-grade PVC.

Common PVC Types to Avoid

Sticker-based PVC cards

Thin plastic sheets without overlays

Cold-laminated cards

Non-standard thickness cards

These fail quickly and increase replacement costs.

Why Best-Quality PVC Is Cost-Effective

Although premium PVC costs slightly more upfront, it:

Lasts 3–5 times longer

Reduces reprints

Maintains professional appearance

Works reliably with access systems

Over time, it is significantly cheaper than low-grade alternatives.

Conclusion

The best quality PVC for ID cards is virgin, CR80-grade PVC with multi-layer construction and heat-laminated protective overlays. This combination ensures maximum durability, print clarity, flexibility, and long-term reliability—especially important in Indian environments.

Choosing the right PVC is not about appearance on day one; it is about performance over years of daily use.

Comments